PRODUCT CATEGORIES

GET IN TOUCH

DETAILED INFORMATION

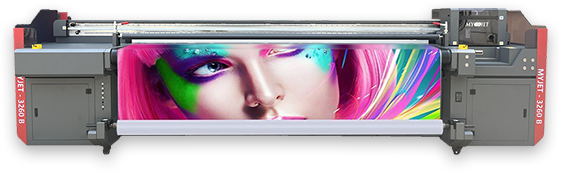

Can be equipped with 8 pcs of Ricoh G5/G6 printheads( 6 pcs of Epson I3200 configuration is also optional), suitable for mass production, with higher precision, higher speed, higher cost-effective.

Advantages

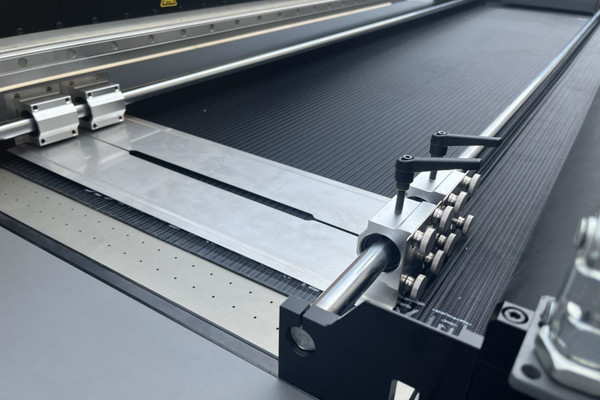

Adjustable sucking platform

3 adjustable sucking zones to solve the problem of insufficient adsorption force for small format segmented printing

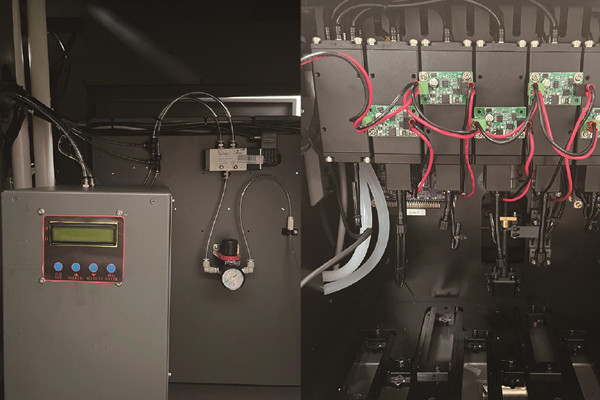

Inks volum display

Standard with ink volume real-time display function

Taking-up and feeding system

The discharge system is equipped with correction tensioning rod, the receiving material adopts torque motor control mode, and the printing platform is equipped with pressing rod device, which can effectively solve the problem of uneven material tension

Special designed edge-pressing system

Optional sliding leather special edging device, sothat special material printing no longer have warping trouble, can better protect the nozzle.

Dule negative-pressure ink system

High precision dual negative pressure system, with the third generation of smart metal secondary ink cartridges, equipped with automatic shutdown ink lock function and ink thermostat system.

Industrial machine frame

The high-strength industrial body can be equipped with up to 12 pcs of Ricoh G5/G6 nozzles in 4 rows to easily achieve high precision and high speed. (EPSON I3200 is optional)

Magnetic suspension motor

It is equipped with magnetic levitation motor to avoid the gap error and mechanical jitter in power transmission, and with 1μmagnetic grid ruler, it can achieve accurate X-direction positioning.

Auxiliary stepping system

The Y-axis rubber roller auxiliary stepping system can effectively solve the printing problem caused by the adsorption difficulty of special materials.

Application

RELATED PRODUCTS

GET IN TOUCH