PRODUCT CATEGORIES

GET IN TOUCH

DETAILED INFORMATION

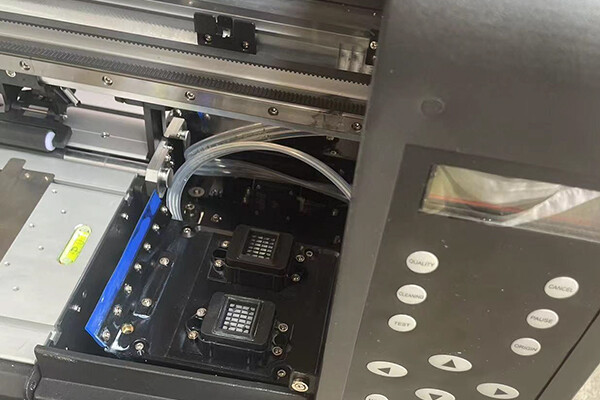

It can be used with 2 EPSONI1600A1/XP600 nozzles to easily meet the needs of high precision, multiple applications.

Overview

Advantages

Hoson board

High-precision, high-speed and stable network port board, delicate printing and bright spray painting

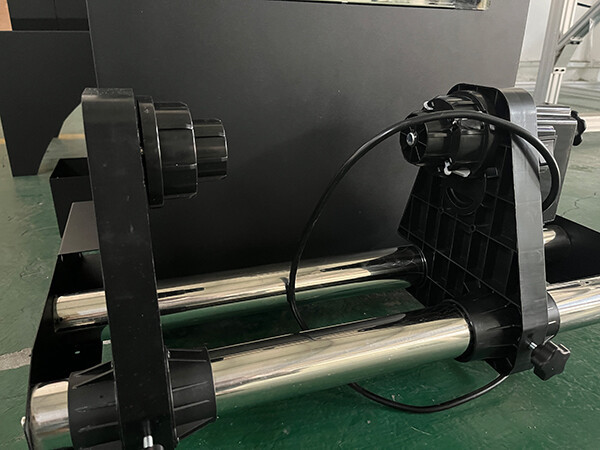

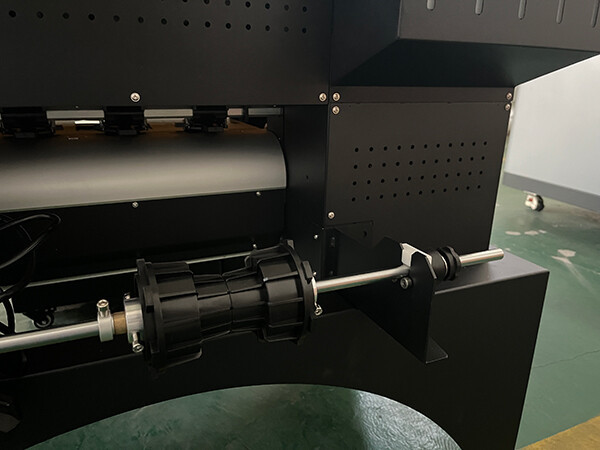

Automatic winding function

The powder shaking machine adopts the automatic induction winding function to save time, effort and labor

Printing + Press

It only needs printing + pressing to complete the printing in two steps.

Color fastness

There is no restriction on fabric material and color, the transfer effect is good, no fear of washing, and the fastness reaches level 4.5

Adjustable transfer temperature

Transfer temperature is 160-170 degrees, cold tearing takes 10-15 seconds, the actual temperature can be adjusted according to different fabrics.

White ink mixing cycle

White ink is stirred and circulated without settling, ensuring smooth printing.

Waste powder recycling

Waste powder recycling technology to avoid waste and save costs

White and CMYK printed

No engraving, no waste discharge, white and CMYK comes out at the same time, good hand feeling, waterproof and washable.

Application

RELATED PRODUCTS

GET IN TOUCH