In the field of UV roll-to-roll printing, traditional equipment has a long history of poor material suitability, wide-format accuracy is difficult to control, frequent production interruptions and other problems, seriously restricting the development of enterprises. According to market research organizations, about 70% of the relevant printing enterprises are plagued by these problems, which greatly affects the production efficiency and profit margins. MYJET in 2025 launched the MJT 3204 UV roll-to-roll printer, with industrial-grade stability, provides an effective solution for 3.2-meter wide-format printing.

I. A Direct Attack On Industry's Pain Points: Three Major Dilemmas of UV Roll-to-roll Printing

(i) Difficulty in adapting materials

There are significant differences in the characteristics of the printing materials on the market, such as light cloth, translucent film and mesh cloth. The survey found that traditional equipment in switching materials, on average, need to spend more than 2 hours debugging tension and corrective parameters. For example, in a sample of 50 printing companies, each changeover resulted in production stoppages and increased production costs.

(ii) The pain of precision degradation

When printing in wide format, the main beam deformation and guide rail jitter problem of traditional equipment is prominent. Industry data show that the resulting picture splicing misalignment, so that the finished product pass rate is generally less than 80%. This not only causes material waste, but also affects product quality, reducing the competitiveness of enterprises in the market.

(iii) The suffering of maintenance costs

Printing head clogging, frequent wear and tear of mechanical parts, resulting in the traditional equipment needs to stop 3 - 4 times a day for maintenance, less than 60% of the effective production time. According to statistics, maintenance costs account for a large proportion of the operating costs of enterprises, becoming a heavy burden on the development of enterprises.

II. Technical Breakthrough: MYJET 3204's Industrial-Grade Stable Architecture

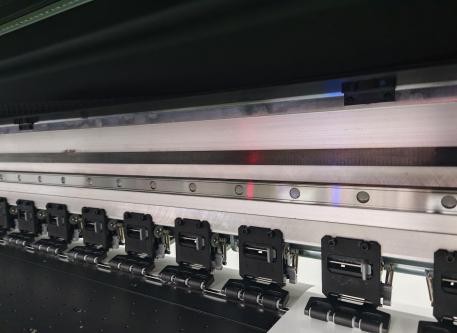

(i) Guardian of Wide-Format Accuracy

The milling process of CNC integrated into the type main beam, in the 3.2-meter span under the straightness error <0.1mm, effectively eliminating the "wave pattern" and splicing color difference. The splicing accuracy of wide-format images printed with this equipment has been greatly improved after practical application tests. The dual guide structure of THK silent guide rail and double slider suppresses transverse vibration and guarantees the stability of printheads under high-speed operation, making the printing accuracy more reliable.

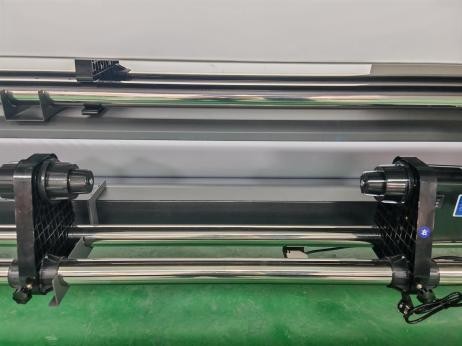

(ii) Commander of All-Material Printing

The double take-up and discharge system combined with the deflection correction tensioning lever can independently control the tension of two rolls of material, which can be well adapted to the difference in ductility of PVC, translucent film and other materials. In actual production, the material can be quickly switched to improve production efficiency. The multi-mode printing engine composed of Hansen i3200 dual-head/quad-head system supports the switching of white color, color white and other modes, which meets the market demand of different products such as car stickers and soft film ceilings.

(iii) Guardian of long-lasting operation

The closed cleaning bin of the aluminum alloy auto-moisturizing ink stack reduces ink evaporation and reduces printhead maintenance frequency. In the return visit to the enterprises using this equipment, it was found that the printhead maintenance cycle was extended by about 50%. Modular upgrade design allows seamless expansion from dual-head to quad-head systems, which facilitates enterprises to flexibly match capacity growth needs according to changes in market order volumes.

III. Efficiency Comparison: Conventional Roll-To-Roll Printer vs. MYJET 3204

IV. Scenario Value: From Pain Point Elimination to Benefit Jump

In the advertising signage market, the demand for large format light cloth continues to grow. the MYJET 3204's 3.2 meter wide light cloth seamless printing function eliminates the splicing process and improves the integrity of the picture, meeting the market's demand for high quality advertising signage and improving the competitiveness of companies in the advertising field.

In terms of industrial decorative materials, the market demand for wood grain film and translucent film shows a steady growth trend. The equipment can adapt to the high intensity production rhythm, realize continuous printing, improve production efficiency, reduce production costs, help enterprises in the field of industrial decorative materials printing advantage.

In the field of customized packaging printing, the market demand for small-lot, diversified packaging is increasing. the MYJET 3204's dual take-up and put-down system supports rapid switching of material types to meet the demand for small-lot customization in customized packaging printing, opening up new market space for enterprises.

V. Conclusion

MYJET 3204 builds a stable base for industrialized production by virtue of "Precision Machinery + Long-lasting Design". In an increasingly competitive market, stable production not only improves efficiency, but also brings reliable profit guarantee to enterprises, leading the industry to develop in the direction of higher quality.

MYJET TECHNOLOGY – STABILITY, THE ULTIMATE EFFICIENCY REVOLUTION

GET IN TOUCH