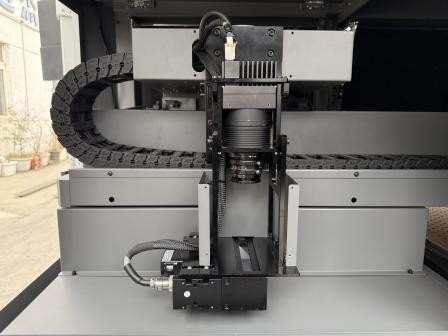

In the UV printing industry development process, visual positioning system (CCD system) has become a key turning point. It integrates industrial imaging technology and intelligent algorithms, completely changing the past dependence on manual positioning, low production efficiency, leading the industry towards a "data-driven" era, with strong automated positioning, dynamic correction and multi-material adaptation capabilities, to promote the printing process towards zero error, flexibility, sustainable direction.

I. Technological Breakthroughs: 3 Major Innovations In Smart Printing

(i) All in one software for Integrated Process

1. Three-in-one software architecture: The device's unique three-in-one software architecture integrates print control, RIP color separation and visual positioning modules into one. Users only need to import the design file with one click, and the system can automatically complete a series of complex operations such as typesetting, color calibration and path planning. The operating interface is designed to be intuitive and easy to understand, greatly reducing the difficulty of operation.

2. Intelligent Positioning Free System: With the 8K industrial camera paired with a high-precision coaxial light source, it can accurately and automatically capture the features of shaped workpieces such as badge grooves and curved surfaces of toys even if the materials are placed randomly. After actual testing, the positioning error is less than 0.1mm, which greatly improves production efficiency and positioning accuracy.

(ii) High-Dynamic Production Model

1. Synchronization of scanning and printing: X-axis magnetic levitation motor drives the printhead to achieve high-speed response, the equipment in the scanning of the Nth workpiece at the same time, can be synchronized with the completion of the printing of the N - 1 workpiece, significant increase in production efficiency, changing the traditional equipment, single-piece operation of the low-efficiency mode.

2. Cyclic continuous operation: with the automatic feeding system, the equipment supports unattended mass production. This feature is especially suitable for the production of small workpieces and high-frequency orders, so that enterprises can effectively respond to such orders and improve the overall production capacity.

(iii) Industrial-Grade Precision Guarantee

1. The 1200DPI resolution combined with the Ricoh G6 printhead accurately reproduces fine lines and gradient textures at the 20μm level, and prints patterns and logos with rich details and natural color transitions, meeting the market demand for printing precision.

2. Intelligent path algorithm automatically optimizes the inkjet angle, effectively solving the common dot misalignment problem when printing on curved surfaces, and ensuring high quality printing on all kinds of complex curved surfaces.

II. Comparison of Core Advantages: Conventional Device vs. MYJET CCD085

III. Application Scenarios: Accurately Empowering Multiple Fields

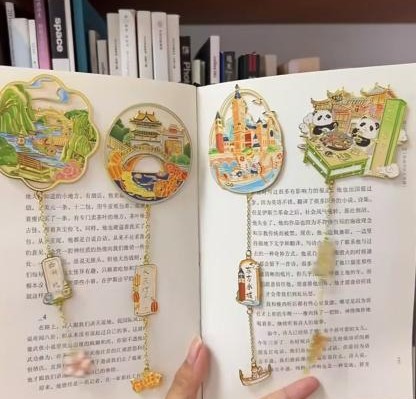

1. Customization of Cultural and Creative Products: In the booming cultural and creative market, consumers' demand for personalized cultural and creative products is growing. MYJET CCD085 is capable of high-definition color printing on badges, metal bookmarks and other small workpieces, which breaks through the limitation of the starting quantity of screen printing, meets the production demand of small batch and multiple varieties of cultural and creative products, and helps cultural and creative enterprises to develop more creative products.

2. Production of Toy Model: The demand for direct printing on multi-curved toys is becoming more and more common in the toy manufacturing industry, and the MYJET CCD085, with its powerful curved surface printing capability, can directly print on the surface of toys, replacing the inefficient pad printing process. Not only that, the printed color transitions are more natural, adding unique visual effects to toys and enhancing their quality and market competitiveness.

IV. Value for Selecting MYJET CCD085

1. Cost reduction: Reduce manual intervention, reduce labor costs, while reducing material waste, reduce the overall cost by more than 30%, saving a lot of operating capital for the enterprise.

2. Increase efficiency: Automated processes greatly shorten the delivery cycle, companies can quickly respond to urgent orders, improve customer satisfaction and enhance market competitiveness.

3. Improve quality: 1200DPI industrial-grade precision brings higher quality to the product, enhances the premium space of the product, and helps the enterprise to get more profits.

4. Sustainability: Supporting environmentally friendly ink and waste ink recycling system, it meets the green manufacturing standard and helps enterprises to practice environmental protection concepts and establish a good corporate image.

Conclusion: Reconfiguring production boundaries with technology

MYJET CCD085 is not only an advanced printing device, but also an important help for enterprises to realize intelligent transformation. With the dual advantages of "precise positioning + data-driven", it is helping global manufacturers break through the limitations of efficiency and precision, seize the first opportunity in the fierce market competition, and reshape the production pattern.

GET IN TOUCH