1. Different Working Principles

UV printers use UV ink cured instantly by ultraviolet light. No coating is needed—prints dry immediately.

Eco-solvent or water-based printers spray ink that dries naturally or with heat as it penetrates the media surface.

2. Different Printable Materials

UV printers can print on almost any material: glass, wood, metal, plastic, leather, acrylic, etc.

Eco-solvent printers are mostly used for flexible materials like photo paper, stickers, lightbox films, vinyl, PVC banners, etc.

3. Different Application Scenarios

UV Printer: Ideal for signage, phone cases, custom gifts, home décor, and industrial decoration.

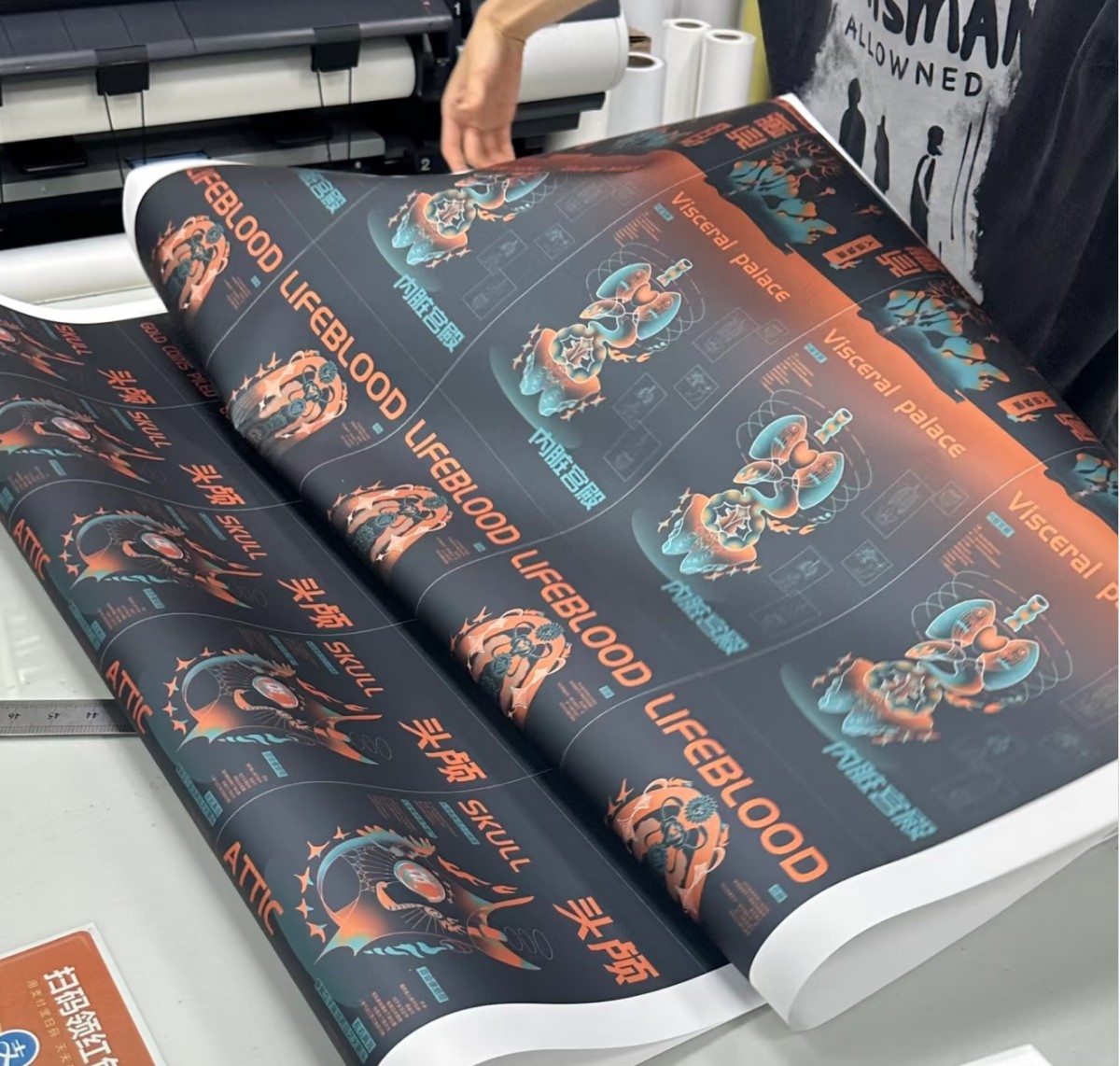

ECO Solvent Printer: Common in advertising prints, posters, roll-up banners, car wraps, and short-term outdoor promotions.

4. Print Quality & Ink Differences

UV prints offer vibrant color, 3D texture effects, white ink, and varnish support for premium output.

Eco-solvent prints are smooth and natural, ideal for photos and posters, but do not support white ink.

5. Durability and Weather Resistance

UV prints are waterproof, UV-resistant, and last 3–5 years outdoors.

Eco-solvent prints may require lamination for outdoor use, as they are less durable without protection.

6. Machine & Operating Costs

UV printers cost more (¥30,000–¥300,000), with higher ink cost, but support high-value multi-material printing.

Eco-solvent printers are more affordable (¥10,000–¥50,000), with simple maintenance and ideal for advertising startups.

7. How to Choose the Right Printer?

Choose a UV printer for personalized, high-margin, multi-material products.

Choose an eco-solvent printer for high-speed, large-format advertising production.

8. MYJET Offers the Right Printing Solution

MYJET provides a wide range of UV flatbed, roll-to-roll, and eco-solvent printers for signage, customization, and industrial use.

GET IN TOUCH