I. Differences in Technical Principles

Introduction of Visual‑Positioning Technology

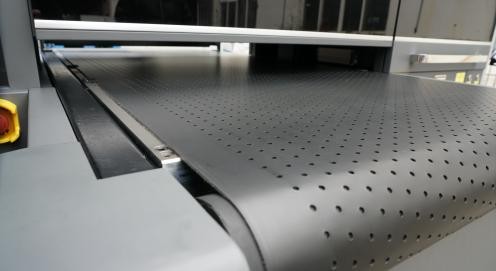

Visual‑positioning UV printers employ high‑precision cameras and image‑recognition algorithms to achieve exact positioning of the print substrate. This technology not only allows for real‑time error correction but also automatically detects the edges and design areas of the workpiece, greatly enhancing print accuracy and consistency. For example, the CCD085 visual‑positioning UV printer leverages this advanced visual‑positioning system to ensure perfect alignment from the original artwork to the finished product, significantly reducing manual setup errors.Working Principle of Traditional UV Printers

Traditional UV printers generally rely on mechanical positioning systems and preset templates. Their positioning accuracy depends on the stability of mechanical components and manufacturing tolerances. During prolonged continuous use or when processing irregularly shaped substrates, traditional machines can drift or misalign, negatively impacting print quality.

II. Performance Comparison

Print Precision

Visual‑Positioning UV Printers: Thanks to continuous visual feedback, the system can make micro‑adjustments in real time, delivering exceptionally high precision—even for highly intricate patterns.

Traditional UV Printers: Accuracy largely depends on initial mechanical setup; complex designs may suffer from detail loss or cumulative alignment errors.

Color Reproduction

Visual‑Positioning UV Printers: Real‑time monitoring and dynamic process adjustment yield smooth color transitions and outstanding detail, making these machines ideal for high‑end advertising, fine art reproduction, and industrial decoration.

Traditional UV Printers: Perform adequately in standardized production runs; however, they can fall short in applications demanding the highest color fidelity and subtle gradations.

III. Efficiency Comparison

Production Speed

Visual‑Positioning UV Printers: Automatic alignment dramatically reduces manual intervention and setup time, boosting throughput in batch production.

Traditional UV Printers: Require repeated manual adjustments and calibrations, extending production cycles; better suited for small runs or standardized output.

Operational Stability

Visual‑Positioning UV Printers: With ongoing system oversight and dynamic correction, these machines maintain stable performance during long, continuous runs and exhibit a lower failure rate.

Traditional UV Printers: Extended operation leads to mechanical wear and accumulated positioning errors, increasing maintenance needs and downtime.

IV. Cost Comparison

Initial Investment

Visual‑Positioning UV Printers: The integration of sophisticated cameras and high‑precision control systems raises upfront costs. Yet for companies demanding superior output quality and high production efficiency, this investment often pays dividends through reduced waste and rework.

Traditional UV Printers: Feature lower purchase prices, making them more accessible for small‑ to medium‑sized enterprises or those with modest precision requirements.

Operational & Maintenance Costs

Visual‑Positioning UV Printers: Automatic correction and inherent system stability translate to lower long‑term maintenance expenses and fewer quality‑related reprints.

Traditional UV Printers: Frequent manual recalibrations and interventions drive up labor and maintenance costs over time.

V. Application Scenarios & Case Studies

High‑End Customization & Advertising

Visual‑positioning UV printers excel in markets that demand the utmost in precision and color accuracy—such as bespoke signage, promotional artwork, and gallery‑quality décor. For instance, posters and decorative panels produced with the CCD085 deliver flawless detail reproduction that captivates viewers.Industrial Manufacturing & High‑Volume Production

Traditional UV printers still hold a competitive edge for standardized, large‑volume runs where cost per unit is paramount. However, as consumer preferences shift toward personalized, high‑quality products, visual‑positioning systems are progressively being adopted in industrial settings to elevate overall efficiency.

VI. Conclusion

A side‑by‑side analysis of visual‑positioning UV printers and traditional UV printers across technical principles, performance, efficiency, and cost reveals that:

Visual‑Positioning UV Printers (e.g., the CCD085) deliver superior print precision, richer color rendition, and faster throughput—ideal for high‑end customization and premium applications. Although they carry a higher initial price tag, their reduced maintenance and rework expenses offer a strong return on investment over time.

Traditional UV Printers offer lower entry costs, fitting the budgets of enterprises focused on standard batch production. Yet they lag behind in detailed printing and long‑term operational stability.

When selecting a UV printer, businesses should weigh their production requirements, budget constraints, and target market demands. As technology advances, visual‑positioning UV printers are poised to supplant traditional models in an ever‑widening range of applications, driving the industry toward greater efficiency and finer print quality.

GET IN TOUCH